Impatience of a Commodity

This project starts as a response to the proposal to design a Bourbon distillery in Boston. Such proposal, its program, and its location immediately involve considering the movement of raw materials over long distances, almost more than thinking about the whiskey production itself. [Corn, yeast, malted barley, rye, and even the correct type of water are produced and or found in the mid-west of the US, 1000 miles away from Boston].

The first-floor plan is designed around a semi-truck’s turning radius. This organizes the site in plan, and separates the production area and the whiskey aging area [called rickhouse - where the barrels are stored]. The trucks can move through the center of the building while delivering raw materials and picking up whiskey barrels.

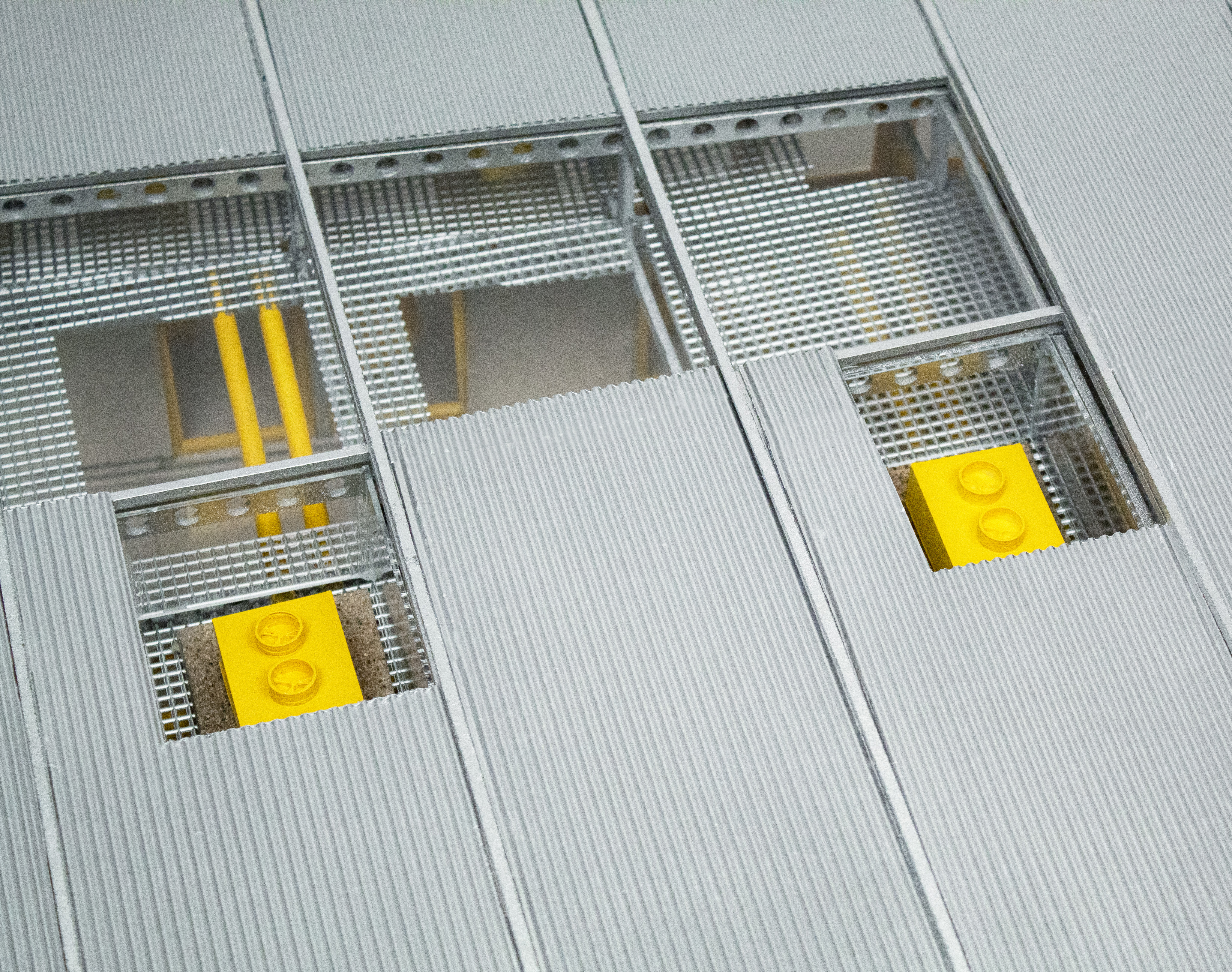

The second floor works differently, more like a computer motherboard. It contains all the offices, control rooms, boiler rooms and laboratories. All the services and circulation hang from the structure, thus never touching the first floor. The second floor should be imagined as an interchangeable piece, as if each motherboard was responsible for producing a particular commodity.

A series of seasonal logistical operations using an overhang bridge crane allow the barrels to be organized in different fashions following the whiskey aging time and the production speed. Students from the nearby Cultural Arts Center can perform and practice in various stages and setups for two years when the biannual show takes place, right before the batch of barrels that make up the seating area and stage have correctly aged.

The modularity of the motherboard allows for a small theatre fly that aligns with the biannual stage.

The result is a choreography between trucks coming in and out, piling barrels organized by a bridge crane, the constant practicing and performing of students, and the movement of the community throughout the seasons.

Harvard GSD | 2022

Supervisor: Emmett Zeifman

This project starts as a response to the proposal to design a Bourbon distillery in Boston. Such proposal, its program, and its location immediately involve considering the movement of raw materials over long distances, almost more than thinking about the whiskey production itself. [Corn, yeast, malted barley, rye, and even the correct type of water are produced and or found in the mid-west of the US, 1000 miles away from Boston].

The first-floor plan is designed around a semi-truck’s turning radius. This organizes the site in plan, and separates the production area and the whiskey aging area [called rickhouse - where the barrels are stored]. The trucks can move through the center of the building while delivering raw materials and picking up whiskey barrels.

The second floor works differently, more like a computer motherboard. It contains all the offices, control rooms, boiler rooms and laboratories. All the services and circulation hang from the structure, thus never touching the first floor. The second floor should be imagined as an interchangeable piece, as if each motherboard was responsible for producing a particular commodity.

A series of seasonal logistical operations using an overhang bridge crane allow the barrels to be organized in different fashions following the whiskey aging time and the production speed. Students from the nearby Cultural Arts Center can perform and practice in various stages and setups for two years when the biannual show takes place, right before the batch of barrels that make up the seating area and stage have correctly aged.

The modularity of the motherboard allows for a small theatre fly that aligns with the biannual stage.

The result is a choreography between trucks coming in and out, piling barrels organized by a bridge crane, the constant practicing and performing of students, and the movement of the community throughout the seasons.

Harvard GSD | 2022

Supervisor: Emmett Zeifman